Imanes de neodimio sinterizados son los imanes más potentes disponibles comercialmente en el mundo, con productos energéticos que oscilan entre 33 y 52 MGOe. Ofrecen una solución ideal para aplicaciones que requieren imanes fuertes y altamente coercitivos disponibles en grandes cantidades a un costo relativamente bajo. Los imanes de neodimio sinterizado se utilizan ampliamente en productos de consumo como teléfonos móviles, parlantes, sujetadores y juguetes, así como en aplicaciones industriales como detectores de metales, filtros de aceite, alternadores, medidores de flujo, y abrazaderas de soldadura. También son esenciales en máquinas de resonancia magnética, vehículos híbridos y eléctricos y turbinas eólicas debido a su alta potencia y tamaño compacto. Los imanes de neodimio sinterizado vienen en varias formas (bloques, anillos, arcos, discos, esferas y más), siendo el revestimiento de Ni-Cu-Ni el recubrimiento más común, aunque también hay otros acabados disponibles.

|

∇ Los imanes permanentes más potentes |

| ∇ Alto rendimiento a bajo costo |

| ∇ Excelente resistencia a la desmagnetización |

| ∇ Opciones para materiales estándar y de alta temperatura |

| ∇ Productos energéticos superiores a 50 MGOe |

Propiedades magnéticas de Imanes de neodimio sinterizados

| Calificación | Br | HcB | hcj | (BH) máx. | Recomendar temperatura máxima de trabajo | ||||||||

| kg | T | koe | ka/m | koe | ka/m | MGOe | kJ/m³ | L/D≥0,7 | |||||

| máx. | mín. | máx. | mín. | mín. | mín. | mín. | mín. | máx. | mín. | máx. | mín. | °C | |

| N30 | 11.2 | 10.8 | 1.12 | 1.08 | ≥10 | ≥796 | ≥12 | ≥955 | 31 | 28 | 247 | 223 | ≤80 |

| N33 | 11.7 | 11.3 | 1.17 | 1.13 | ≥10,5 | ≥836 | ≥12 | ≥955 | 34 | 31 | 271 | 247 | ≤80 |

| N35 | 12.1 | 11.7 | 1.21 | 1.17 | ≥10,9 | ≥868 | ≥12 | ≥955 | 36 | 33 | 287 | 263 | ≤80 |

| N38 | 12.6 | 12.2 | 1.26 | 1.22 | ≥11,3 | ≥899 | ≥12 | ≥955 | 39 | 36 | 311 | 287 | ≤80 |

| N40 | 12.9 | 12.6 | 1.29 | 1.26 | ≥11,6 | ≥923 | ≥12 | ≥955 | 41 | 38 | 327 | 302 | ≤80 |

| N42 | 13.2 | 12.9 | 1.32 | 1.29 | ≥12 | ≥955 | ≥12 | ≥955 | 43 | 40 | 342 | 318 | ≤80 |

| N45 | 13.7 | 13.3 | 1.37 | 1.33 | ≥12,5 | ≥955 | ≥12 | ≥955 | 46 | 43 | 366 | 342 | ≤80 |

| N48 | 14.0 | 13.7 | 1,40 | 1.37 | ≥12,9 | ≥1027 | ≥12 | ≥955 | 49 | 46 | 390 | 366 | ≤80 |

| N50 | 14.3 | 14.0 | 1.43 | 1,40 | ≥13,1 | ≥1043 | ≥12 | ≥955 | 51 | 48 | 406 | 382 | ≤80 |

| N52 | 14.5 | 14.3 | 1,45 | 1.43 | ≥13,3 | ≥1138 | ≥11 | ≥876 | 53 | 50 | 422 | 398 | ≤70 |

| N54 | 14.6 | 14.4 | 1.46 | 1.44 | ≥13,6 | ≥1150 | ≥11 | ≥876 | 55 | 52 | 438 | 414 | ≤70 |

| N56 | 14.8 | 14.6 | 1,48 | 1.46 | ≥13,7 | ≥1160 | ≥11 | ≥876 | 57 | 54 | 454 | 430 | ≤70 |

| 30M | 11.2 | 10.8 | 1.12 | 1.08 | ≥10,9 | ≥868 | ≥14 | ≥1114 | 31 | 28 | 247 | 223 | ≤100 |

| 33M | 11.7 | 11.3 | 1.17 | 1.13 | ≥10,5 | ≥836 | ≥14 | ≥1114 | 34 | 31 | 271 | 247 | ≤100 |

| 35M | 12.1 | 11.7 | 1.21 | 1.17 | ≥10,9 | ≥868 | ≥14 | ≥1114 | 36 | 33 | 287 | 263 | ≤100 |

| 38M | 12.6 | 12.2 | 1.26 | 1.22 | ≥11,3 | ≥899 | ≥14 | ≥1114 | 39 | 36 | 311 | 287 | ≤100 |

| 40M | 12.9 | 12.6 | 1.29 | 1.26 | ≥11,6 | ≥923 | ≥14 | ≥1114 | 41 | 38 | 327 | 302 | ≤100 |

| 42M | 13.2 | 12.9 | 1.32 | 1.29 | ≥12,0 | ≥955 | ≥14 | ≥1114 | 43 | 40 | 342 | 318 | ≤100 |

| 45M | 13.7 | 13.3 | 1.37 | 1.33 | ≥12,5 | ≥995 | ≥14 | ≥1114 | 46 | 43 | 366 | 342 | ≤100 |

| 48M | 14.0 | 13.7 | 1,40 | 1.37 | ≥12,9 | ≥1027 | ≥14 | ≥1114 | 49 | 46 | 390 | 366 | ≤100 |

| 50M | 14.3 | 14.0 | 1.43 | 1,40 | ≥13,1 | ≥1043 | ≥14 | ≥1114 | 51 | 48 | 406 | 382 | ≤100 |

| 52M | 14.5 | 14.3 | 1,45 | 1.43 | ≥13,3 | ≥1138 | ≥14 | ≥1114 | 53 | 50 | 422 | 398 | ≤100 |

| 54M | 14.6 | 14.4 | 1.46 | 1.44 | ≥13,6 | ≥1150 | ≥14 | ≥1114 | 55 | 52 | 438 | 414 | ≤100 |

| 30H | 11.2 | 10.8 | 1.12 | 1.08 | ≥10 | ≥796 | ≥17 | ≥1353 | 31 | 28 | 247 | 223 | ≤120 |

| 33H | 11.7 | 11.3 | 1.17 | 1.13 | ≥10,5 | ≥836 | ≥17 | ≥1353 | 34 | 31 | 271 | 247 | ≤120 |

| 35H | 12.1 | 11.7 | 1.21 | 1.17 | ≥10,9 | ≥868 | ≥17 | ≥1353 | 36 | 33 | 287 | 263 | ≤120 |

| 38H | 12.6 | 12.2 | 1.26 | 1.22 | ≥11,3 | ≥899 | ≥17 | ≥1353 | 39 | 36 | 311 | 287 | ≤120 |

| 40H | 12.9 | 12.6 | 1.29 | 1.26 | ≥11,6 | ≥923 | ≥17 | ≥1353 | 41 | 38 | 327 | 302 | ≤120 |

| 42H | 13.2 | 12.9 | 1.32 | 1.29 | ≥12,0 | ≥955 | ≥17 | ≥1353 | 43 | 40 | 342 | 318 | ≤120 |

| 45H | 13.7 | 13.3 | 1.37 | 1.33 | ≥12,5 | ≥995 | ≥17 | ≥1353 | 46 | 43 | 366 | 342 | ≤120 |

| 48H | 14.0 | 13.7 | 1,40 | 1.37 | ≥12,9 | ≥1027 | ≥17 | ≥1353 | 49 | 46 | 390 | 366 | ≤120 |

| 50H | 14.3 | 14.0 | 1.43 | 1,40 | ≥13,0 | ≥1034 | ≥17 | ≥1350 | 51 | 48 | 406 | 382 | ≤120 |

| 52H | 14.5 | 14.3 | 1,45 | 1.43 | ≥13,3 | ≥1138 | ≥17 | ≥1350 | 53 | 50 | 422 | 398 | ≤120 |

| 30SH | 11.2 | 10.8 | 1.12 | 1.08 | ≥10,1 | ≥804 | ≥20 | ≥1592 | 31 | 28 | 247 | 223 | ≤150 |

| 33SH | 11.7 | 11.3 | 1.17 | 1.13 | ≥10,6 | ≥844 | ≥20 | ≥1592 | 34 | 31 | 271 | 247 | ≤150 |

| 35SH | 12.1 | 11.7 | 1.21 | 1.17 | ≥11,0 | ≥876 | ≥20 | ≥1592 | 36 | 33 | 287 | 263 | ≤150 |

| 38SH | 12.6 | 12.2 | 1.26 | 1.22 | ≥11,4 | ≥907 | ≥20 | ≥1592 | 39 | 36 | 311 | 287 | ≤150 |

| 40SH | 12.9 | 12.6 | 1.29 | 1.26 | ≥11,6 | ≥939 | ≥20 | ≥1592 | 41 | 38 | 326 | 302 | ≤150 |

| 42SH | 13.2 | 12.9 | 1.32 | 1.29 | ≥12,4 | ≥987 | ≥20 | ≥1592 | 43 | 40 | 342 | 318 | ≤150 |

| 45SH | 13.7 | 13.2 | 1.37 | 1.32 | ≥12,6 | ≥1003 | ≥20 | ≥1592 | 46 | 42 | 366 | 334 | ≤150 |

| 48SH | 14.0 | 13.7 | 1,40 | 1.37 | ≥12,9 | ≥1027 | ≥20 | ≥1592 | 49 | 46 | 390 | 366 | ≤150 |

| 50SH | 14.3 | 14.0 | 1.43 | 1,40 | ≥13,0 | ≥1034 | ≥20 | ≥1592 | 51 | 48 | 406 | 382 | ≤150 |

| 52SH | 14.5 | 14.3 | 1,45 | 1.43 | ≥13,3 | ≥1138 | ≥20 | ≥1592 | 53 | 50 | 422 | 398 | ≤150 |

| 28uh | 10.8 | 10.4 | 1.08 | 1.04 | ≥9,6 | ≥764 | ≥25 | ≥1989 | 29 | 26 | 231 | 207 | ≤180 |

| 30UH | 11.2 | 10.8 | 1.12 | 1.08 | ≥10,1 | ≥804 | ≥25 | ≥1989 | 31 | 28 | 247 | 223 | ≤180 |

| 33UH | 11.7 | 11.3 | 1.17 | 1.13 | ≥10,7 | ≥852 | ≥25 | ≥1989 | 34 | 31 | 271 | 247 | ≤180 |

| 35UH | 12.1 | 11.7 | 1.21 | 1.17 | ≥10,8 | ≥860 | ≥25 | ≥1989 | 36 | 33 | 287 | 263 | ≤180 |

| 38uh | 12.6 | 12.2 | 1.26 | 1.22 | ≥11,3 | ≥899 | ≥25 | ≥1989 | 39 | 36 | 311 | 287 | ≤180 |

| 40UH | 12.9 | 12.6 | 1.29 | 1.26 | ≥11,3 | ≥899 | ≥25 | ≥1989 | 41 | 38 | 326 | 302 | ≤180 |

| 42uh | 13.2 | 12.9 | 1.32 | 1.29 | ≥11,6 | ≥923 | ≥25 | ≥1989 | 43 | 40 | 342 | 318 | ≤180 |

| 45uh | 13.7 | 13.3 | 1.37 | 1.33 | ≥12,5 | ≥995 | ≥25 | ≥1989 | 46 | 43 | 366 | 342 | ≤180 |

| 28EH | 10.8 | 10.3 | 1.08 | 1.03 | ≥9,8 | ≥780 | ≥30 | ≥2388 | 29 | 26 | 231 | 207 | ≤200 |

| 30EH | 11.2 | 10.8 | 1.12 | 1.08 | ≥10,1 | ≥804 | ≥30 | ≥2388 | 31 | 28 | 247 | 223 | ≤200 |

| 33EH | 11.7 | 11.3 | 1.17 | 1.13 | ≥10,3 | ≥820 | ≥30 | ≥2388 | 34 | 31 | 271 | 247 | ≤200 |

| 35EH | 12.1 | 11.7 | 1.21 | 1.17 | ≥10,5 | ≥836 | ≥30 | ≥2388 | 36 | 33 | 287 | 263 | ≤200 |

| 38EH | 12.6 | 12.2 | 1.26 | 1.22 | ≥11,3 | ≥899 | ≥30 | ≥2388 | 39 | 36 | 311 | 287 | ≤200 |

| 40EH | 12.9 | 12.5 | 1.29 | 1.25 | ≥11,3 | ≥899 | ≥30 | ≥2388 | 41 | 38 | 326 | 302 | ≤200 |

| 42EH | 13.3 | 12.8 | 1.33 | 1.28 | ≥11,6 | ≥923 | ≥30 | ≥2388 | 43 | 40 | 342 | 318 | ≤200 |

| 45EH | 13.7 | 13.2 | 1.37 | 1.32 | ≥12,5 | ≥995 | ≥30 | ≥2388 | 46 | 42 | 366 | 334 | ≤200 |

| 28AH | 10.8 | 10.3 | 1.08 | 1.03 | ≥9,6 | ≥764 | ≥35 | ≥2785 | 29 | 26 | 231 | 207 | ≤230 |

| 30AH | 11.2 | 10.8 | 1.12 | 1.08 | ≥9,6 | ≥764 | ≥35 | ≥2785 | 31 | 28 | 247 | 223 | ≤230 |

| 33AH | 11.7 | 11.3 | 1.17 | 1.13 | ≥9,6 | ≥764 | ≥35 | ≥2785 | 34 | 31 | 271 | 247 | ≤230 |

| 35AH | 12.1 | 11.7 | 1.21 | 1.17 | ≥9,6 | ≥764 | ≥35 | ≥2785 | 36 | 33 | 287 | 263 | ≤230 |

| 38AH | 12.6 | 12.2 | 1.26 | 1.22 | ≥9,6 | ≥764 | ≥35 | ≥2785 | 39 | 35 | 311 | 278 | ≤230 |

Solución de revestimiento de superficies

Nota: La resistencia a la corrosión varía según la forma del producto.

| Material de revestimiento | Espesor | Comportamiento | Resistencia a la corrosión | Observación | ||||

| PCT | spray de sal | Humedad y temperatura | Ácido / Alcalino | Aceite | ||||

| Zn (Zn blanco) | ≥ 5 micras | Blanco | ----- | ♦♦ | ♦♦♦ | ----- | ♦ | |

| Zn (ZN chapado en color) | ≥ 5 micras | Iridiscencia | ----- | ♦♦♦ | ♦♦♦♦ | ----- | ♦ | |

| Ni+Cu+Ni | ≥ 15 micras | Astilla | ♦♦♦ | ♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦ | ♦♦♦ | |

| Ni+Cu+Ni+Sn | ≥ 15 micras | Astilla | ♦♦♦♦ | ♦♦♦♦ | ♦♦♦♦♦ | ----- | ----- | Excelente desempeño en soldadura |

| Ni químico | ≥ 5 micras | Astilla | ♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦ | ♦♦♦ | |

| Epoxy | ≥ 12 micras | Negro o gris | ♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦ | Poca resistencia al desgaste |

| Pasivado | ≤ 2 micras | Negro o gris | ----- | ----- | ♦♦♦ | ----- | ♦♦♦ | |

| Al | ≥ 3 micras | Gris plateado | ♦♦♦♦ | ♦♦♦ | ♦♦♦♦ | ----- | ♦♦♦ | Alto rendimiento en encuadernación con cola |

| Al+epoxi | ≥ 15 micras | Negro o gris | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | Poca resistencia al desgaste |

| Zn+Al | ≥ 10 micras | Astilla o gris astilla | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ----- | ♦♦♦♦♦ | |

| Everluber | ≥ 5 micras | Oro | ♦♦♦♦ | ♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦ | |

| teflón | ≥ 5 micras | Negro | ♦♦ | ♦♦♦ | ♦♦♦♦♦ | ♦♦♦♦♦ | ♦♦♦ | Buena resistencia al desgaste |

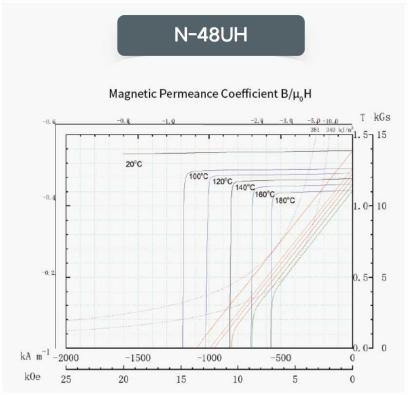

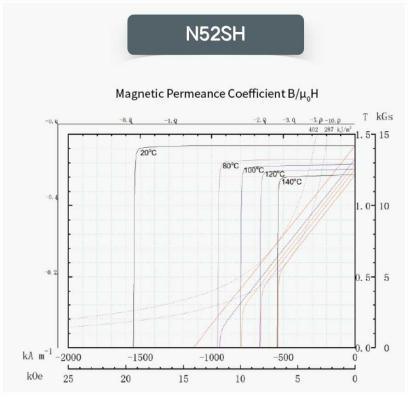

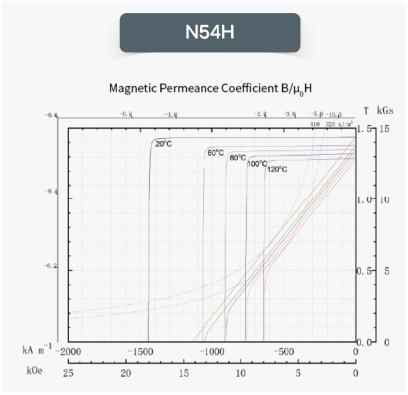

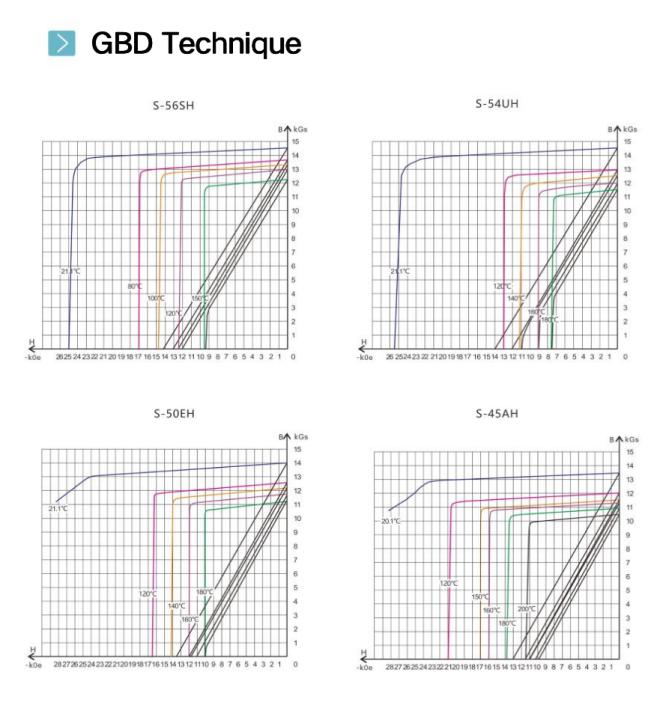

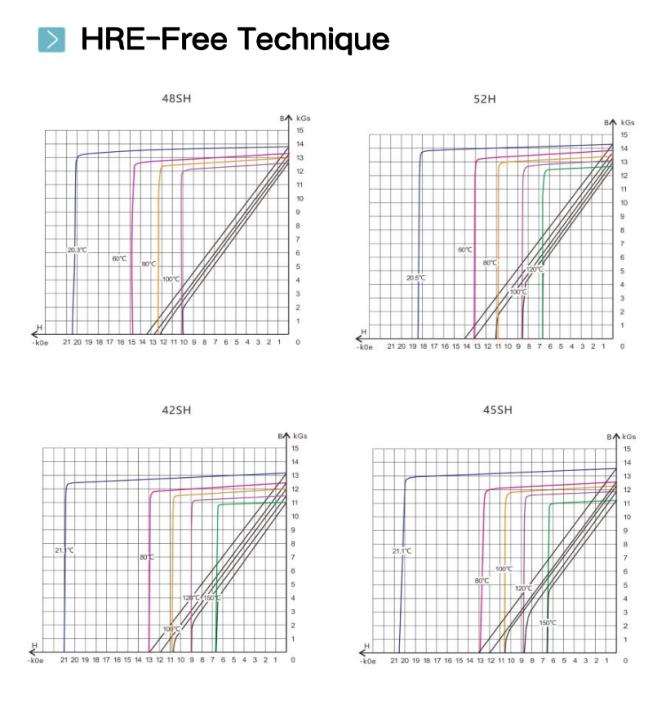

Curva de desmagnetización

Flujo de proceso